PAT testing explained

- Home

- Services

PAT testing explained – everything you need to know about PAT testing

Our guide answers all your questions about PAT tests in an easy and straight-forward way.

We are often asked, “What is a PAT Test?” We always try to find out what the customer wants to know.

We often find out that the legal aspects of PAT tests are what people want to know about.

What is an Electrical PAT Test? Our guide will help you to understand the legal requirements that may apply in your industry or business.

What is a PAT Test?

The PAT test involves a regular inspection to ensure that certain types of electrical appliances are safe for use. The purpose of the test is to reduce electrical incidents in workplaces.

The full PAT should consist of both visual and in-depth checks using PAT specialist equipment. The test checks earth continuity, insulation resistance, and lead polarity.

Certain appliances require only a simplified test called PAT Insulation Test.

After a PAT, each appliance must be marked as ‘passed or failed’. It is ideal to keep a log of all the test results.

Some electrical products do not require PAT testing. Further down the page, we explain in detail which items need to be PAT-tested.

What does PAT stand for?

The acronym PAT stands for Portable Appliance Test .

The current legislation does not define a portable appliance. However, it is generally understood to be “anything that plugs into an outlet and has a plug on it”.

The word portable is misleading. In reality, there are seven categories of appliances that should undergo PAT tests or at the very least, a visual inspection.

- Fix appliances

- Stationary Appliances

- It appliances

- Moveable appliances

- Portable Appliances

Chargers, cables and other accessories - Hand held appliances

You can read more in detail about these categories by scrolling down to the page titled ‘What categories of electrical appliances are tested in PAT?

Is PAT testing a legal requirement?

The PAT test is not a requirement of law.

The UK law states, however, that electrical equipment must be maintained in a safe state.

It is also their legal duty to protect the employees as well as the general public.

It has become standard to meet this requirement because PAT tests are one of the best ways of doing this. This is especially true for environments with high risks or complexes.

You can read specific guidelines about electrical equipment in the workplace by reading a variety of laws:

PAT Testing Regulations UK

– Health & Safety at Work Act, 1974

The Electricity at Work Regulations, 1989

– Work Equipment Regulations, 1998

– Management of Health & Safety at Work Regulations, 1999

What are the penalties if I don’t meet my legal obligations?

Depending on the severity of the situation, the penalty for not meeting legal obligations on electrical appliance safety can be as high as 2 years’ imprisonment, as well as an unlimited financial penalty.

Who is responsible for electrical appliance safety?

The ‘Employer’ is responsible for electrical appliance safety.

In larger businesses a ‘competent person’ is often appointed by the employer, whose role is to make sure the company is compliant.

Which items should be PAT tested?

There are 2 main factors that determine whether or not an item should be PAT tested:

– The electrical ‘class’ of the item

– The ‘category’ of the item

We explain more about these in the following sections.

What are ‘electrical classes’ in PAT testing?

Electrical appliances can be classified into three main categories: Class 1, Class 2 and Class 3. Class 1 is the most hazardous, while Class 3 is the least.

Class 1 appliances need a full PAT test, while class 2 appliances only require a PAT insulation test. A full PAT is required for Class 1 appliances, whereas Class 2 appliances only need an insulation PAT. Class 3 appliances do not need any PAT testing.

Class I Appliances

The insulation of this type is minimal and it relies solely on the earth to protect.

Class 1 appliances

The electrical equipment is safer because it has more insulation. It doesn’t need a ground to protect itself.

Class 2 appliances

Low voltage appliances, also known as Class 3, are considered the most safest electrical appliances. The charging lead may have to undergo PAT testing.

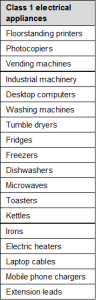

Example of class 1 appliances

Class 1 appliances carry this symbol:

The following appliances are usually (but not always) electrical class 1:

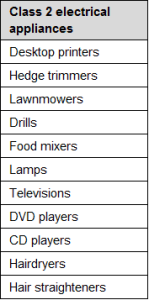

Examples of Class 2 appliances:

Class 2 appliances carry this symbol:

The following appliances are usually (but not always) electrical class 2:

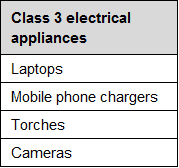

Examples of Class 3 appliances:

Class 3 appliances carry this symbol:

The following appliances are electrical class 3:

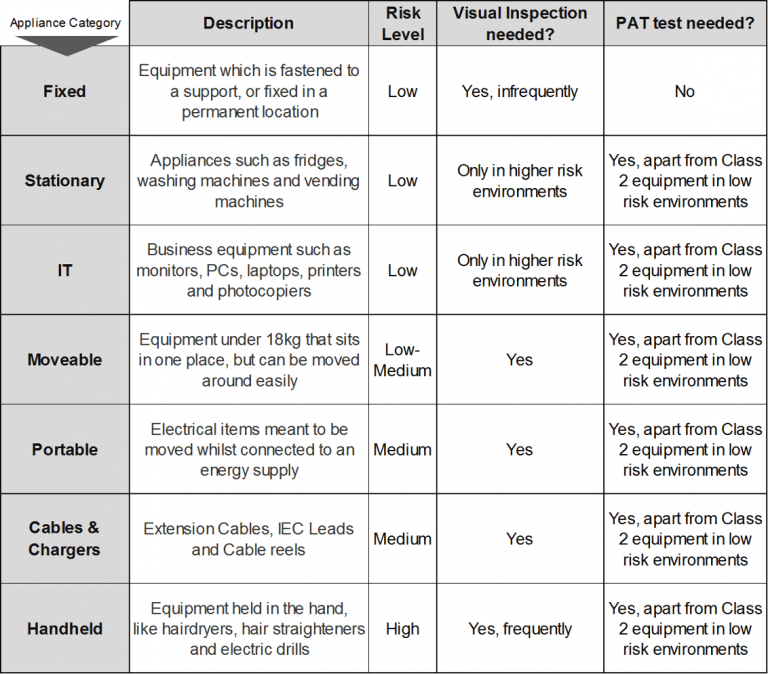

What are the ‘categories’ of electrical appliance in PAT testing?

As mentioned in section 2, there are 7 categories of electrical appliance which require some level of testing, either a simple visual inspection, or a full PAT test:

– Fixed appliances

– Stationary appliances

– IT appliances

– Moveable appliances

– Portable appliances

– Cables and chargers

– Hand Held appliances

The table below explains these categories in more detail:

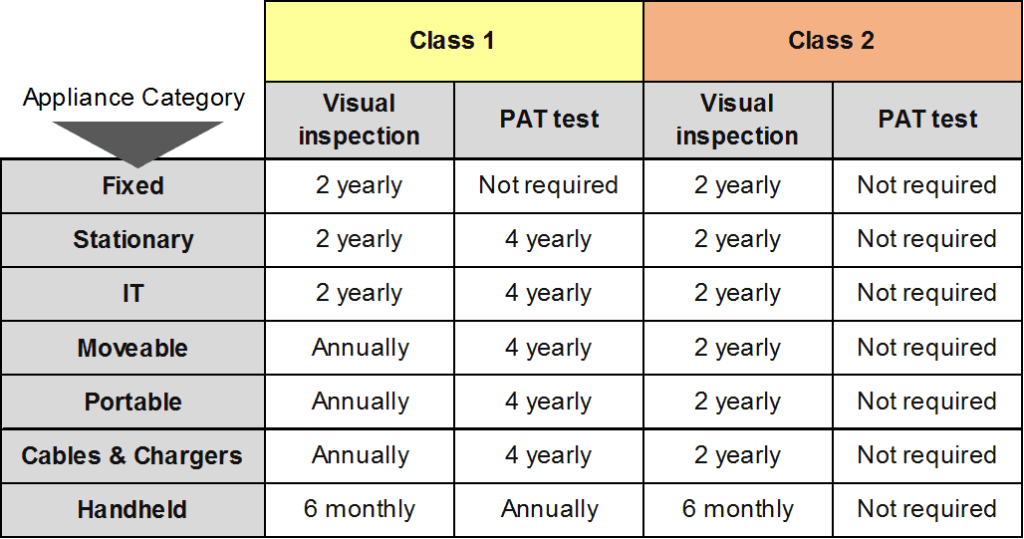

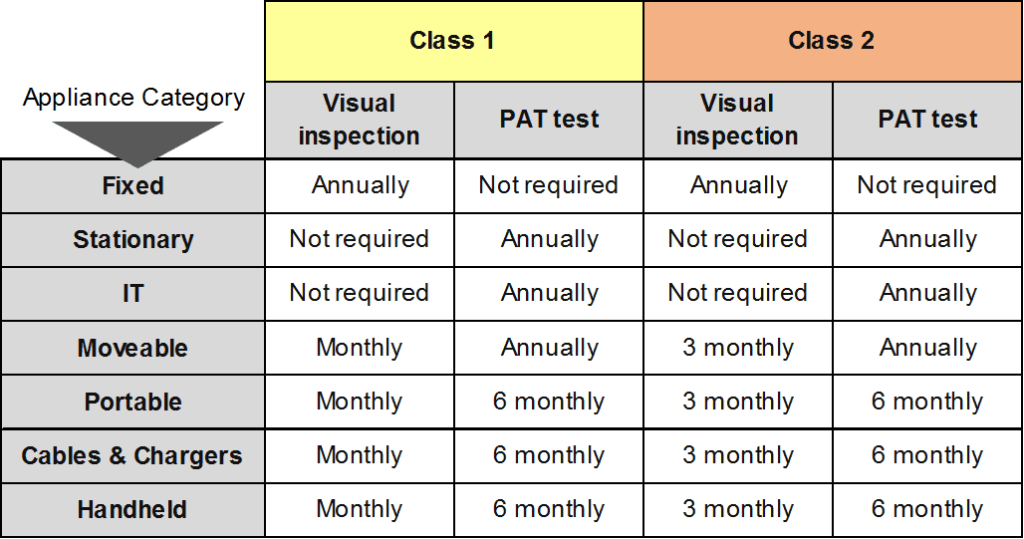

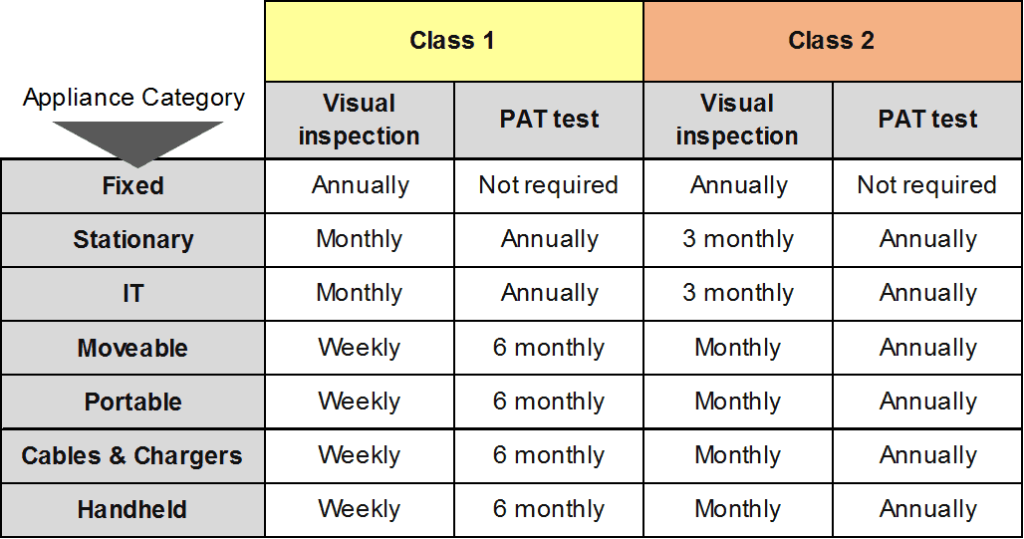

How often should items be PAT tested?

There are no specific rules for the frequency of PAT tests. However, the regulations say that the level of precaution taken should be ‘appropriate’ to the risk.

There are 3 main criteria that determine PAT testing frequency:

– the risk level of the working environment

– the electrical class of the appliance

– the category of the appliance

The Health and Safety Executive also recommends taking the following into consideration as necessary:

– manufacturer’s recommendations

– the age of the equipment

– frequency of use

– foreseeable misuse of the equipment

– effects of any modifications or repairs

– the history of the item

Our tables below tell you the recommended frequency of PAT testing and visual inspections based on the 3 main criteria.

Low Risk Environments:

Low-Medium Risk Environments:

Medium Risk Environments:

High Risk Environments:

Extremely High Risk Environments:

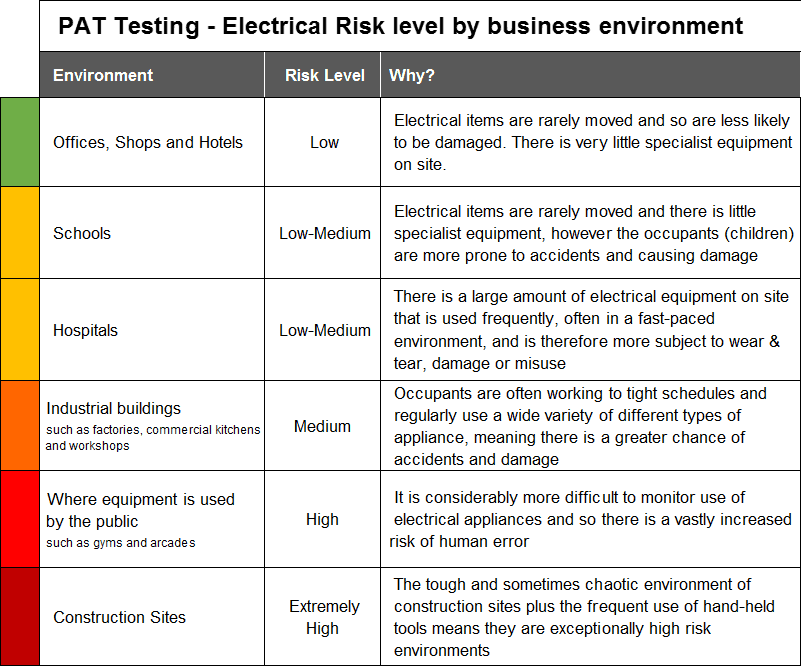

How do I know if my business is high, medium or low risk?

There are 3 main factors that are taken into account when assessing the electrical risk of a business for PAT testing:

- The risk level of the environment

- The type of equipment being used

- Who will be interacting with the equipment

For example, in an office setting where equipment is relatively static and there is a regular team using it day to day, there is much less risk than on a construction site.

On a construction site, hand-held, potentially dangerous equipment is in regular use and groups of workers tend to switch in and out and therefore the risk is much higher.

The table below gives an idea of the likely risk level of different types of business:

Can my business carry out its own PAT testing?

Yes, your business can carry out its own PAT tests, as long as the person doing the testing is a ‘competent’ person.

This means they should:

– have adequate knowledge of electricity

– have adequate experience of electrical work

– know how to carry out a visual inspection

– know how to carry out a PAT test

– understand potential hazards & precautions to take when PAT testing

– be able to decide whether it’s safe for PAT testing to continue

If you decide to do your own PAT testing we would strongly recommend taking a PAT testing course as it’s important to perform the PAT tests correctly.

You will also need to invest in some PAT testing equipment. After a professional has completed their work they will issue a PAT certificate.

EICR TESTING BY MT High Tech ltd

Electrical engineers or electricians with experience should conduct the EICR.

Contractors will discuss operational restrictions with clients for commercial or rented property. It may be necessary to close down the phone line or server for a short time during the inspection.

There are also areas that an electrician cannot access. For example, cables that run through walls and floors that require the removal of plaster or floor coverings.

The electrician and the client will have to agree on a sample rate that determines how many sockets are tested. Both parties can agree to increase the size of the test sample if any defects are found during the inspection.

The electrician must disconnect the installation’s electrical supply from the main electricity source of the building to perform the EICR. The IET Wiring Regulations will be used to check that the electrical installation meets the required standards.